A national average of 12% rejects and wastes of mango production is realized annually (BAS, 2010). This level of losses is sometimes higher in Pangasinan as it experiences typhoons, strong winds, untimely harvest and pests and diseases. These are the common factors that affect mango yield quantity and quality.

Annually, pest and disease infestations severely affect the quality of fresh mangoes. One of the infestations that severely affect the mango industry in the province is the Cecidfly damage locally known as “kurikong” on the fruit peel. Most of the fruit damaged by this insect pest are just “skin-deep” hence the fruits are still edible, but they remain unmarketable or have very low prices due to market preference for more visually appealing fruits. Mango growers are left with volumes of reject fruits in their farms.

Mango rejects are usually the fruits not in conformity with the market quality standards. They are irregular in shape and size, with mechanical injuries, physiologically immature, and with insect damages. These reject fruits can be marketable by processing intervention. Processed mango products have higher market values. One of the market acceptable mango products is mango wine. Handling and distribution are more convenient to potential markets nearby. While mango growers are engaged in quality production of fresh mango fruits, their housewives can earn extra income by processing mango fruits.

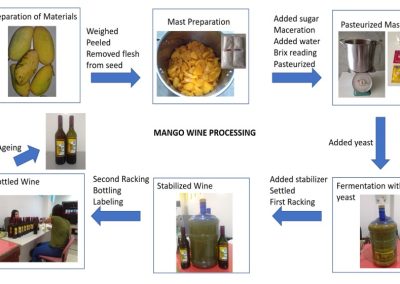

Mango Wine Processing

Ripe mango fruits were utilized for mango wine processing. A total of 5 kgs of ripe mango fruits were processed into mast. Mango fruit mast was mixed with sugar and water to attain a Brix reading of 21. A special strain of Saccharomyces cerevisiae (dry yeast) produced for wine production was used for the fermentation. To sterilize the mast, one tablet of Campden (sodium metabisulfite) was added 24 hr before adding the yeast.

Fermentation parameters were determined including the alcohol percentages. The fermentation was stopped after 1 month using sodium metabisulfite. After 6 months of fermentation, racking was done to separate the clear liquid part from the sediments to produce the final product and transferred them to sterilized bottles. Each bottle contained 750 ml of clarified wine. Packaging material especially the label was also developed for marketability aspect.

One month after adding the yeast, the wine was stabilized to stop the fermentation. First racking was done 2 months after adding stabilizer. Second racking to further remove the sediments was done one month after first racking. After 2 months, the bottling was done to start the bottle ageing. A total of 20 bottles of mango wine with a net content of 750 ml or a total of 18.75 L was produced.

An estimated 20% (vol/vol) of the total volume of stabilized wine was discarded to remove the sediments during first racking, second racking, and bottling.

The final alcohol content of the wine was determined using a wine alcohol tester. The alcohol content was at 14% (vol/vol). The color was light yellow.